- Design Of Bell Crank Lever Action

- Suspension Bell Crank

- Bell Crank Linkage Examples

- Bell Crank Assembly

- Bell Cranks And Linkage

Parametric design charts are proposed for the central-lever steering linkage, generated for simplified reference configuration mechanisms, the geometry of which is defined by only four parameters. This highlights the fact, yet not generally acknowledged, that the steering law ensured by a mechanism with adjacent central joints (known as bell crank mechanism), can be identically generated by a triple central joint variant of the same. Particular configurations are identified in which the length of the central lever does not affect the wheel-to-wheel transmission function of the mechanism, permitting a simplified synthesis for the cases in which the maximum stroke of the input member is imposed as a design specification.

What is a lever?

A lever is a rigid bar that pivots about a fulcrum. It transmits an input motion and force, (the effort) through the lever pivoting on a fulcrum to a resistance force called a load.

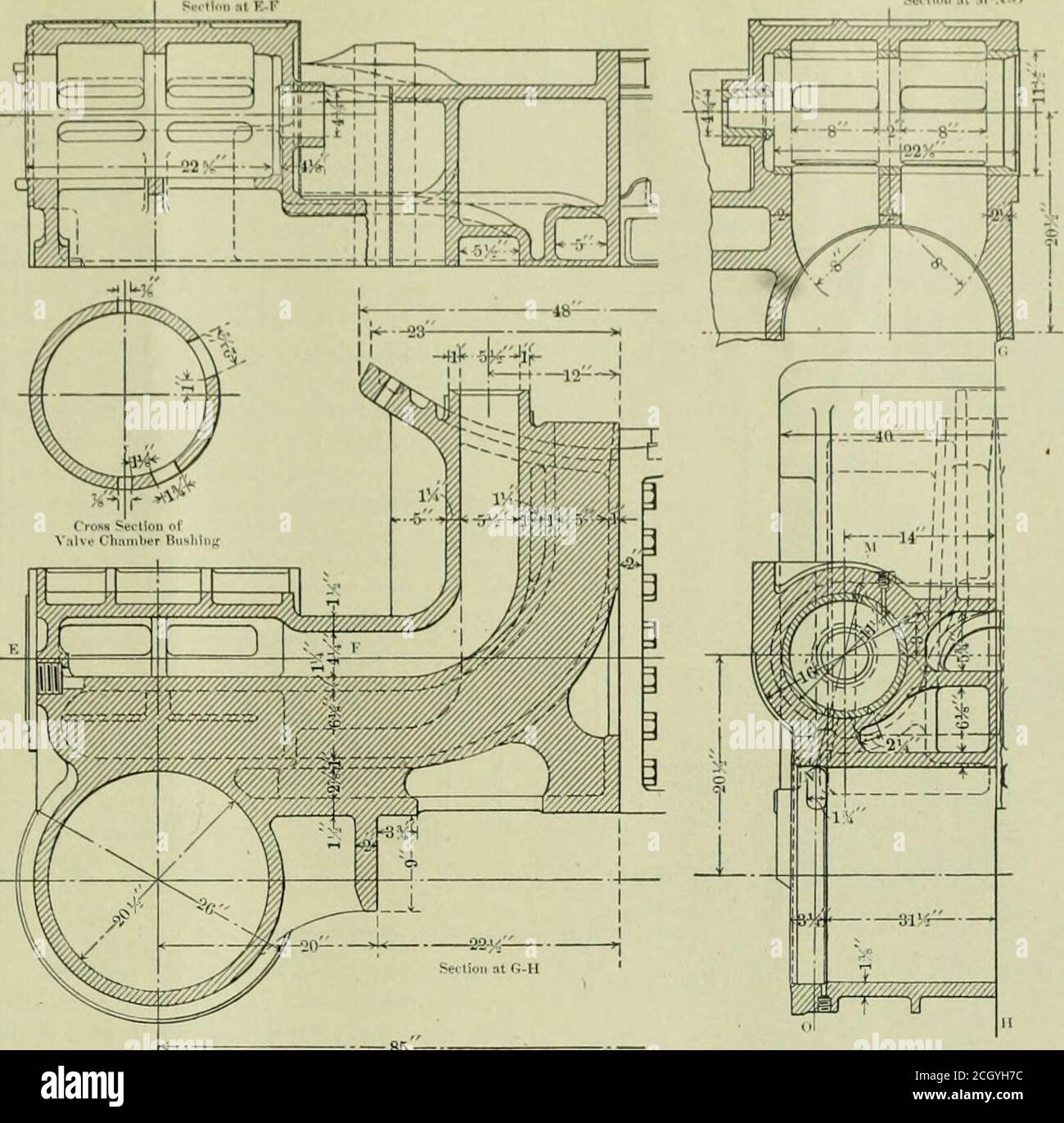

Bell Crank Design 3 The bellcrank that you design will need to fit the exact ball bearing, ball joint linkages, and spring shown in the supporting information. Figure III-2 shows details of the exact positioning of the components. The bell crank shown in III-2 is basically symmetric. Figure III-2: Positioning of related parts. Learn and revise mechanical devices with BBC Bitesize for GCSE Design and Technology AQA. Bell crank linkages change the direction of force through 90°. It is important when using levers. A bell-crank lever consists of a long arm, 8 1 2 in. Long, and a short arm 4 in. Long, at right angles to each other. Calculate the force to be applied at right angles to the end of the long arm to overcome a resistance of 40 lbf acting at 30° to the vertical of the short arm. Video Lecture on Problem on Bell Crank Lever from Design of Cotter Joint, Knuckle Joint,Levers and Offset Links Chapter of Design of Machine for Mechanical.

Design Of Bell Crank Lever Action

Load

The load is anything that is being moved by a lever.

Effort force

The effort force is the energy applied to a lever to move a load.

Fulcrum

The fulcrum is the point at which the lever pivots. A lever may rest on a fulcrum or it may swivel on an axle, e.g. a see-saw (class 1 lever) and a wheel barrow (class 2 lever).

Classes of lever

There are three classes of levers. Each class of lever has the load and effort force in specific positions relative to the fulcrum.

Suspension Bell Crank

Class 1 lever

A Class 1 lever has the fulcrum between the load and the effort force.

Class 2 lever

A Class 2 lever has the load between the fulcrum and the effort force.

Bell Crank Linkage Examples

Class 3 lever

A Class 3 has the effort force between the load and the fulcrum.

Bell Crank Assembly

Bell Crank LeverA bell crank lever is an angled Class 1 lever. It is a Class 1 lever because the fulcrum is between the load and the effort force. The bell crank lever is used when the effort force must be at an angle, usually a right angle, to the load. |

Bell Cranks And Linkage

CantileverA cantilever is a beam that is fixed at one end only. Load is applied to the unsupported end. A cantilever may be classified as a type of Class 1 lever as fulcrum is between the effort force and the load. |